| Supplier management system |

|

Chinyi's suppliers are formally selected and continually evaluated. New suppliers are selected after careful evaluation and successful completion of Chinyi's vendor application process.

(1) In each quarter, our system will audit all suppliers and implement the classification system strictly

(2) Level-I supplier: original factory, agents, authorized distributor

(3) Level-II supplier: OEM, ODM, EMS factories

(4) Level-III supplier: with an annual turnover of more than $50M, with third-party certification (ERAI, IDEA, ISO)

(5) Level-IV supplier: with an annual turnover of more than $20M and who have been engaged in the component supply industry for more than 10 years

(6) Level-V supplier: Other suppliers (including new suppliers)

|

|

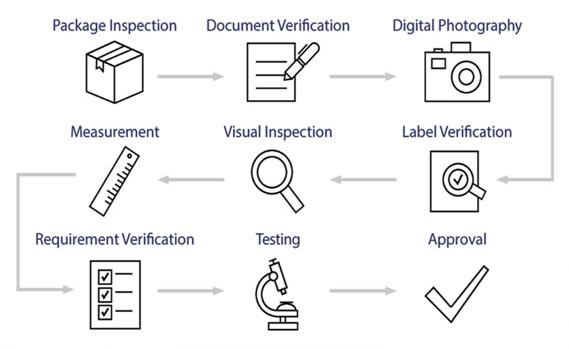

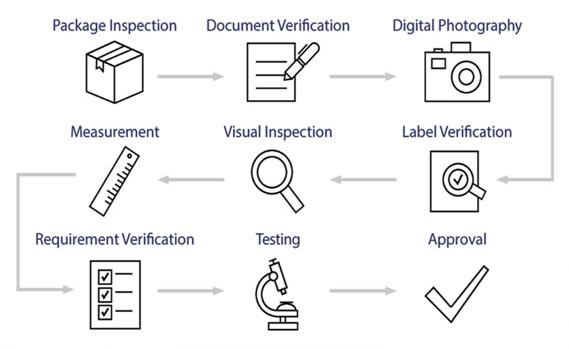

| Inspection process |

|

Step 1 Visual Inspection

We will perform the visual inspection when all goods entry warehouse, and make all the detailed inspection records that including manufacturer、part number、quantity、date code and ROHS standards inspection.

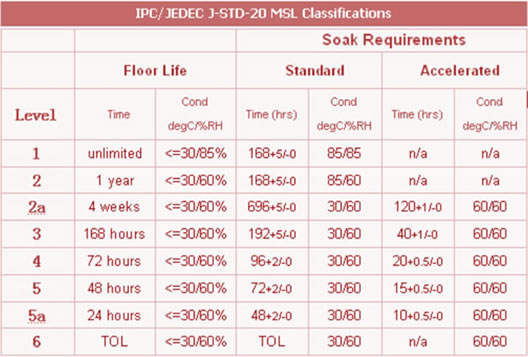

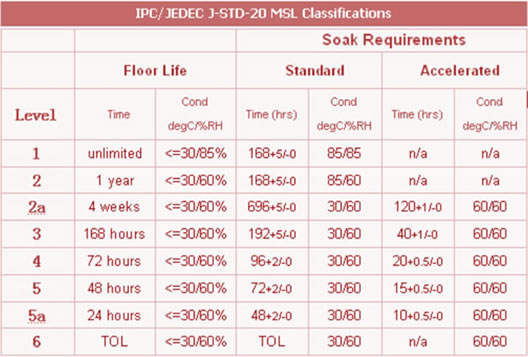

(1) External package inspection, whether the packaging is intact and complete, whether the package materials meet the corresponding MSL standard requirements

(2) Marking inspection, comprehensive inspection, check the original factory datasheet

(3) Part visual inspection, whether the Pin is deformed、oxidized、blackened and other signs etc.

(4) HS CODE inspection to check whether the information is consistent with the invoice and packing list

Step 2 Engineer Re-inspection

Once the parts found suspicious during visual inspection, or if the supplier channel is not a "tier 1 supplier" in the system, the parts should be re-inspected by the engineer

(1) Re-check the visual inspection process

(2) Check the labels of manufacturer according to the quality control database

(3) Barcode scanning inspection

(4) Check the Lot number、date code, wafer and package type with original factory

(5) Simple electrical performance inspection

|

|

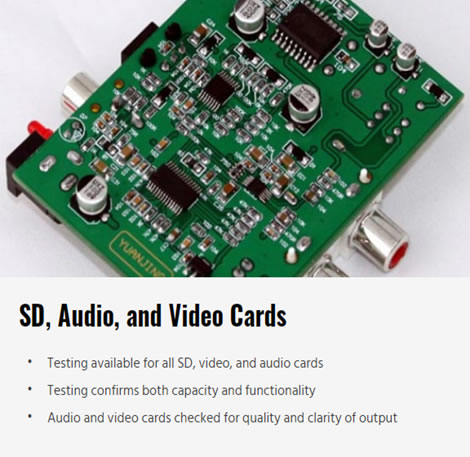

| Functionality testing |

|

Chinyi Enterprise is in close cooperation with third party laboratory to provides full functionality testing. With over sixty functionality tests in practice daily, Chinyi is fully equipped to manage custom testing programs for any project.

|

| Warehousing, packaging, transportation standards |

|

As electronic components are sensitive items and have strict requirements for storage, packaging and transportation. Chinyi abide by the original factory for all levels of material storage environment standards strictly, from static electricity protection、humidity control to constant temperature control, we adhere to the original factory requirements for the corresponding items to ensure that the quality of goods "zero defects" delivered to customers.

(1) Antistatic packing

(2) Humidity sensitivity control

(3) Constant temperature control

(4) Establish archives for each customer's packaging、labels and identification requirements

(5) Choose the fastest, safe and economical shipping way for each customer

|

|

| Quality control database management |

|

Chinyi ensure customers to use "zero defect" products with strict quality control process and strong IT system, real-time quality control database management is the most strong backing. All details of goods incoming and outgoing will be uploaded to our quality control database for archiving. Including:

(1) Quality control sheet to record the details of warehousing goods information

(2) Samples archived

(3) Take photos and archive for all purchase details

(4) Take photos and archive for all shipment details

(5) Documents of unqualified goods are archived, and suppliers submit to the corresponding supplier review process of the hierarchical management system

(6) Quality inspection analysis report archived

|

| RMA process |

|

If there is any questions about the quality of any goods sold by Chinyi, please follow our RMA procedure to ensure we can provide you with the most timely solution. Please contact our sales representative as soon as possible and provide the following necessary documents:

(1) Invoice and packing list, so that we can call the details of the customer's suspected goods in our quality control database immediately

(2) Please send us the quality inspection report by Email, so that we can contact the relevant manufacturers to check quality problems and eliminate potential risks immediately

(3) Chinyi promises to provide positive counter-measures and solutions within 24 hours upon receipt of customers' RMA application

(4) Sample inspection: please help to provide samples of products with questionable quality and will submit to the original factory or third-party authoritative testing agency for detailed testing and analysis, so as to find the root cause of quality problems and deal with quality risks more effectively.

|